| PVC发泡管生产线, PVC芯层发泡管生产设备 |

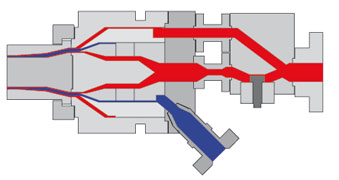

生产线采用三层复合共挤技术,使用两台锥形双螺杆挤出机、复合共挤机头、真空定径和循环喷淋冷却系统,牵引切割装置等。两台锥双挤出机确保PVC混合料能 良好塑化和高产量挤出。复合共挤机头由一个喂料块和复合管模共同组成、可高效生产芯层发泡管、同时也可选配带螺旋槽并能匀速转动的芯棒生产内螺旋发泡管及 空壁内螺旋管。牵引采用双履带式,上履带浮动,气缸夹紧,直联式减速机单独驱动履带,进口变频调速。切割采用PLC控制系统,显示屏设定长度,自动定长切 割。

PVC芯层发泡管的中间层是芯层发泡层,比PVC实壁管重量约轻20-30%;它比实壁管更耐冲击,其环向刚性为后者的八倍。同时它可显著降低流水噪音,特别适合于高层建筑排水。被广泛应用于建筑排水工程、工业防腐、液体运输及农业排灌等领域。

该管材为三层共挤复合排水管,其内外两层为硬质PVC及加工改良助剂,以保证管材足够的强度及其它物 理性能,中间层是由特殊配方的PVC及进口加工助剂组成的,其相对密度为0.7-0.9g/cm3,该层结构为细 微封闭孔状,这种特殊结构,巧妙地利用了材料力学中的工型结构原理。

|

|

|

|

The 25% cost saving solution!

We offer PVC foam core pipemachine for production of 3-layer PVC-pipes. Cost savings in production of up to 26% mainly on material savings by an foam core is the vital argument to compete with compact pipes in non-pressure applications!

Using virgin or recycling material has been the major advantage of this technology. Standard fitting systems, as known for compact pipes, can be used. The high outpu using a combination of two or three extruders in a production setting. Smaller dimensions are using double-strand technology. Another big advantage of our technology is the low-cost formulation recommended.

Pipes are usually produced to national standards. The main standards are EN 1401-1 and EN 13476 as well as US F 891. Wall thickness is determined in a way that ring stiffness classes of 2, 4, 6 and 8 kN can be achieved. Highest classes already done are 16 kN.

A typical application is sewerage pipes reaching a market share of 85 % on comparable applications in Europe, which have totally erased compact pipes for this application. There is a clear potential for massive growth in the region of middle and near east.

Development priorities are higher filling of foam core and skin, 3-extruder settings with colouring of the outside skin only and extended use of recycling material in the middle layer. |